High-precision GNSS antennas play a critical role in positioning, surveying, mapping, autonomous driving, geodetic monitoring, and robotics. Although GNSS modules and receivers continue to improve, the antenna remains the primary element that determines signal quality, stability, multipath rejection, and positioning accuracy. A well-designed GNSS antenna significantly enhances performance, especially in challenging environments.

This guide aims to help you understand how high-precision GNSS antennas are engineered, what performance indicators matter, and which structural factors contribute the most to reliability and accuracy.

The wireless antenna element—also known as the passive antenna or ''antenna body'' — is responsible for receiving and radiating GNSS signals. Its structure has three key components: substrate material, antenna form, and feed-point design.

The substrate material determines dielectric properties, radiation efficiency, size, and environmental stability. Common GNSS antenna substrate materials include:

Light weight

Cost-effective

Suitable for compact designs

Good mechanical stability

Higher dielectric constant

Enables smaller form factors

Improved strength

Easy to manufacture

Low dielectric loss

High stability

Better high-frequency performance

Popular for multi-band GNSS antennas

Ultra-high dielectric

Very small size

Excellent environmental stability

Ideal for L1/L2/L5 compact GNSS antennas

For antennas used in automotive, UAV, and geodetic applications, the radome material also influences performance:

High strength

Weather resistance

Good shielding

Long service life

Ceramic and metal-based structures usually deliver the highest precision because their dielectric properties remain stable under temperature changes. In Harxon's product development process, we have consistently observed that substrate stability directly correlates with phase-center repeatability.

The geometry of the antenna greatly affects its gain, bandwidth, and multipath rejection capabilities.

Single ceramic patch or board

Low cost

Easy to produce

Suitable for consumer-level GNSS applications

Multiple stacked dielectric layers

Wider frequency bandwidth

Better multipath suppression

Supports full-band or multi-band GNSS

Metal patch + dielectric + ground

High gain

Stable phase center

Excellent for RTK, surveying, UAV, and precision farming

In high-precision scenarios, multi-layer and stacked patch antennas show clear advantages. In our own Harxon multi-band GNSS antennas, layered structures allow us to control resonant modes more accurately, achieving both wide bandwidth and consistent gain across L1/L2/L5/B1/B2/G1/G2 frequencies.

The feed-point configuration dramatically affects:

Phase Center Error (PCE)

Gain symmetry

Axial ratio

Multipath resistance

Simplest structure

Acceptable for low-precision applications

Phase center stability around ±2 mm

Reduced phase center variation

Better performance in multi-band GNSS

Stability within ±1 mm

Best balance across frequency bands

Excellent symmetry

Stability within ±0.5 mm or better

The general rule is: the more optimized the feed structure, the better the GNSS antenna's comprehensive performance. In professional-grade antennas like those we design at Harxon, multi-feed systems are essential for centimeter-level RTK accuracy.

The PCB is not merely a mounting platform—it influences electromagnetic behavior, mechanical stability, and filtering performance.

A well-designed PCB helps:

Improve signal integrity

Optimize ground plane effects

Lower noise

Enhance multi-band consistency

High-precision GNSS antennas often require:

Low-loss PCB material

Multi-layer routing

Carefully designed ground and vias

Shielding isolation zones

Inferior PCB design can cause distorted radiation patterns, reduced gain, or a high axial ratio. At Harxon, we treat PCB design as one of the core determinants of antenna quality, not just a mechanical component.

The Low-Noise Amplifier (LNA) is one of the most influential active components because GNSS satellite signals are extremely weak—often below –130 dBm.

The LNA must:

Amplify weak signals

Maintain low noise figure

Provide stable gain across GNSS bands

| Parameter | Importance |

Gain | Ensures adequate signal strength |

Noise Figure (NF) | Lower NF = better sensitivity |

1 dB Compression Point | Prevents distortion under strong interference |

Linearity | Ensures clean amplification |

High-precision applications—RTK, PPP, surveying—cannot tolerate noise figure instability. In Harxon's antennas, multi-stage LNAs are used to achieve optimal gain distribution while maximizing signal purity.

Modern environments are full of wireless noise—from LTE, WiFi, UHF, C-band, and in-vehicle systems. GNSS signals can easily be overwhelmed if filtering is inadequate.

SAW Filters

Stable

Good band selectivity

Effective at narrowband GNSS frequencies

BAW Filters

Higher performance than SAW

Excellent out-of-band rejection

Ideal for L5/B2a signals

LC Filters

Simple

Low cost

Used as secondary filtering stages

Filter Function

Reject out-of-band interference

Maintain in-band flatness

Reduce insertion loss

Protect LNA from overload

In Harxon engineering practice, filtering is not optional—it is essential. Strong filtering dramatically improves accuracy in electromagnetic-noisy environments such as cities, ports, agriculture machinery, or autonomous vehicles.

A metal shielding cover protects the LNA and PCB from:

EMI (electromagnetic interference)

PCB cross-talk

Environmental noise

Voltage fluctuations

Internal shielding also improves:

GNSS positioning stability

Multi-band consistency

Low-elevation signal capture

High-precision antennas always include a shielding layer. Without it, even a good antenna element can perform poorly in real-world use.

Beyond electrical design, mechanical construction impacts durability and long-term accuracy.

Critical factors include:

Radome strength

Waterproofing level

Thermal stability

Vibration resistance

UV resistance

For professional surveying, agriculture, and autonomous driving, an antenna must deliver stable performance despite extreme temperature, shock, and long operation times. At Harxon, many of our antennas undergo rigorous environmental testing—temperature cycling, vibration, salt-spray, humidity—to ensure long-term reliability.

When evaluating or selecting a high-precision GNSS antenna, consider the following core indicators:

The most important factor in high-precision applications. Lower PCE = better accuracy.

A stable high-elevation pattern improves sky coverage.

Low axial ratio improves multipath rejection.

Lower NF = better sensitivity and signal clarity.

Strong filtering ensures reliable operation in interference-heavy environments.

Durability directly affects long-term performance.

Through years of development at Harxon, we have confirmed that precision results from the balanced optimization of all structural components—not just one specification. A good GNSS antenna is not defined by gain alone or material alone, but by the harmonious integration of design, electronics, mechanics, and environmental engineering.

The performance of a high-precision GNSS antenna is determined by a complex combination of structural and electronic factors—substrate materials, antenna geometry, feed-point design, PCB layout, LNA amplification, filtering components, and environmental shielding. Each piece contributes to stability, accuracy, and reliability.

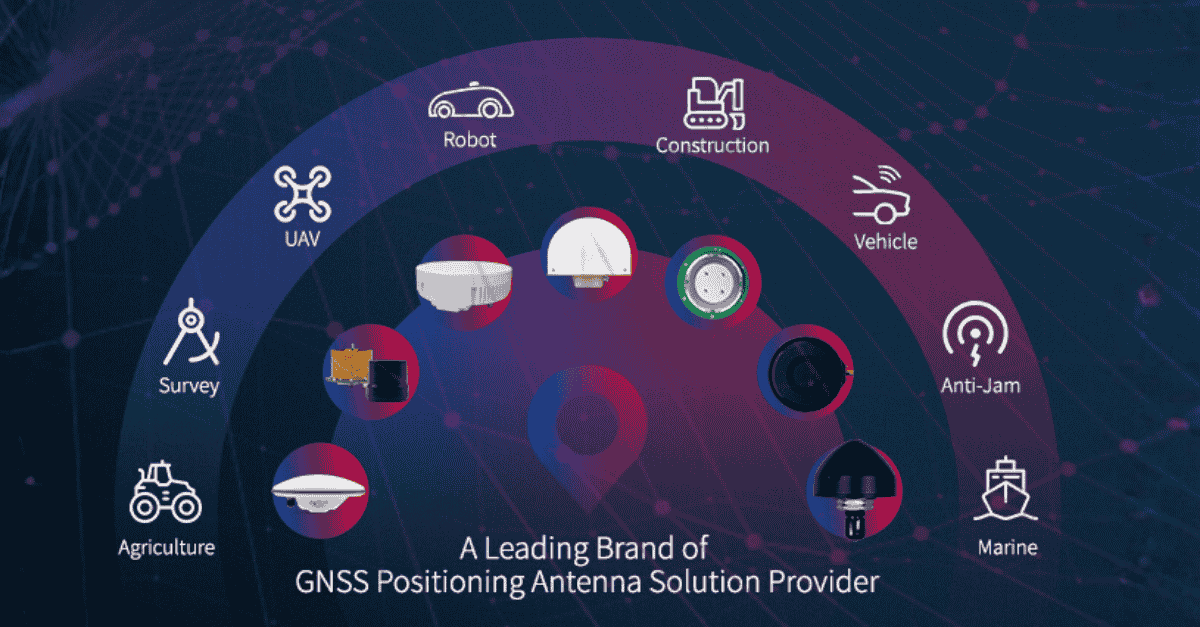

Understanding the structural breakdown of GNSS antennas allows engineers, integrators, and product designers to make better decisions—and helps ensure stable, centimeter-level accuracy across diverse applications such as surveying, robotics, agriculture, and autonomous systems.